LVC Ultra

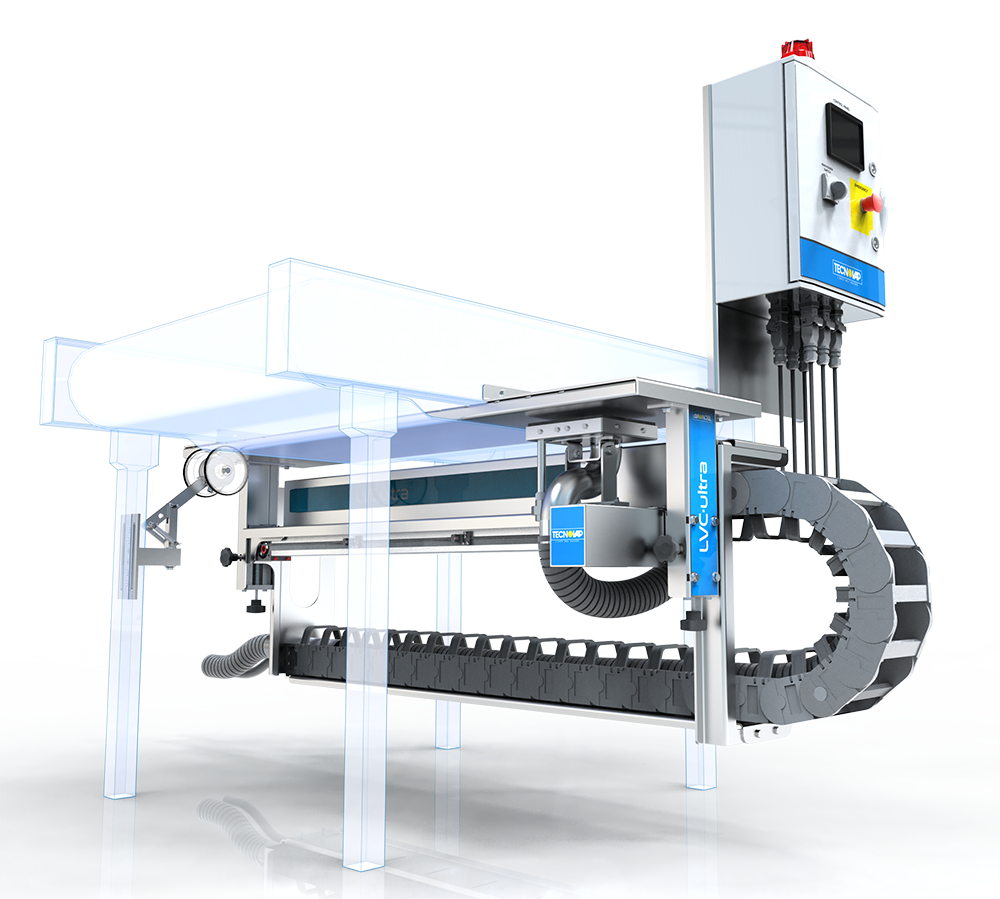

Completely automatic belt cleaning head with linear actuator, for mesh and belt.

LVC Ultra

Completely automatic belt cleaning head with linear actuator, for mesh and belt.

LVC Ultra

FULLY-AUTOMATED CLEANING HEAD

- AISI 304 stainless-steel structure

- Programming of cleaning head working positions and working cycles

- Automatic movement of the steam diffuser

- Customizable dimensions up to 2000mm

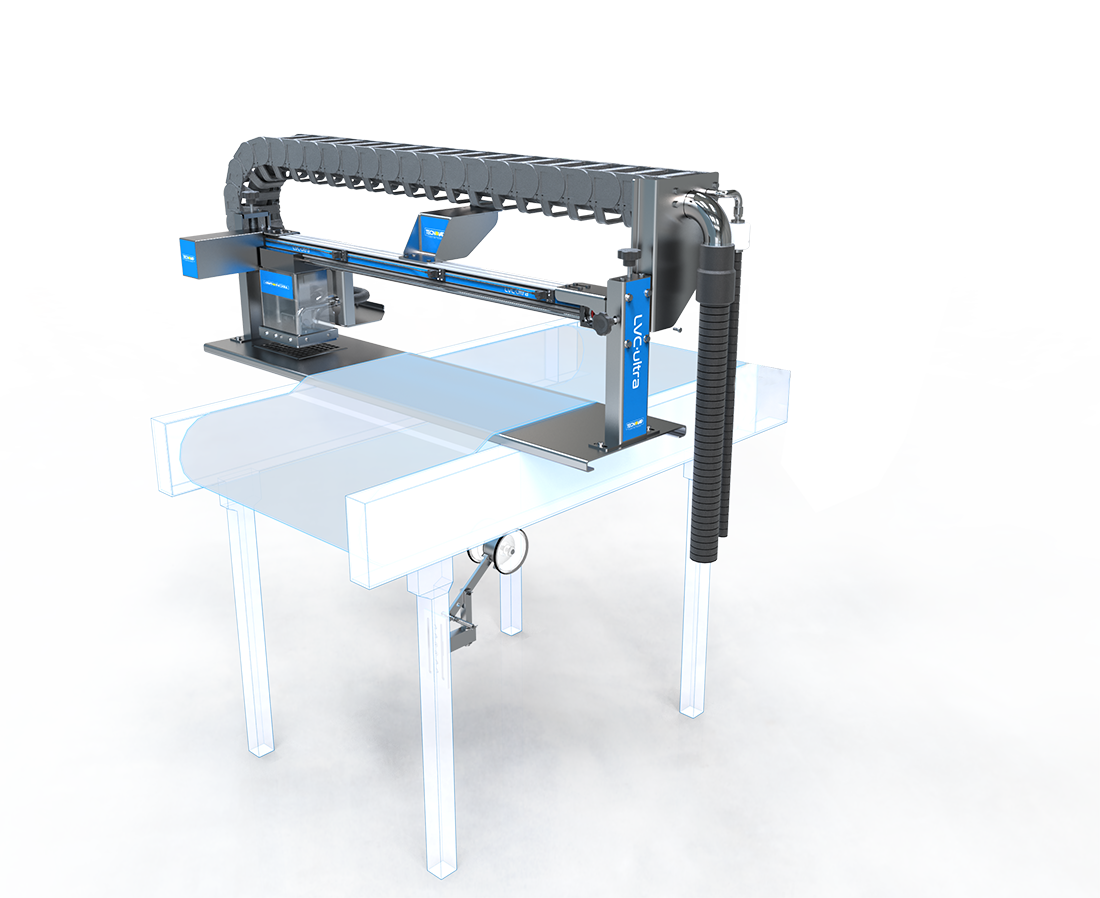

Operating diagram

This type of belt cleaning tool offers the possibility to decide the position of the diffuser and to personalize the duration of the cleaning phase based on the belt.

Below a diagram showing how the belt cleaning head works

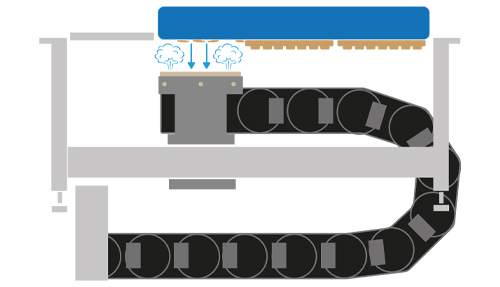

1^ POSITION

Beginning of the cleaning cycle. The diffuser moves onto the 1st section of the belt.

2^ POSITION

Once the cleaning of the 1st section has been completed, the diffuser automatically moves onto the 2nd section.

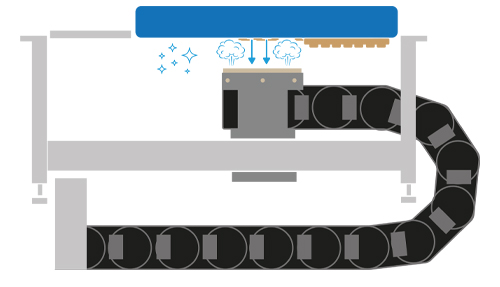

1^ POSITION

Beginning of the cleaning cycle. The diffuser moves onto the 1st section of the belt.

2^ POSITION

Once the cleaning of the 1st section has been completed, the diffuser automatically moves onto the 2nd section.

3^ POSITION

Movements continue until the total width of the belt has been reached.

4^ POSITION

When the cleaning cycle is complete, the diffuser will automatically go back to the rest position.

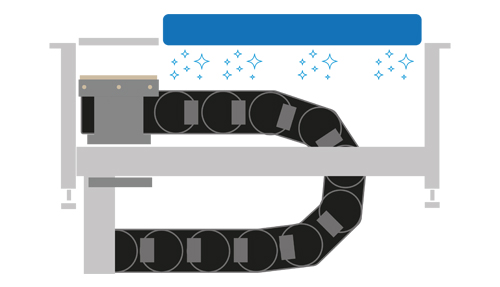

3^ POSITION

Movements continue until the total width of the belt has been reached.

4^ POSITION

When the cleaning cycle is complete, the diffuser will automatically go back to the rest position.

Electrical control box

The belt cleaning head is provided with an electrical control box with a touchscreen display for managing all functions of the steam generator and belt cleaning head.

- Programming of cleaning head working positions

- MINIMUM – MEDIUM – MAXIMUM steam

- Detergent injection

- Overheated water injection for the diffuser cleaning

- Vacuum

- Emergency stop button

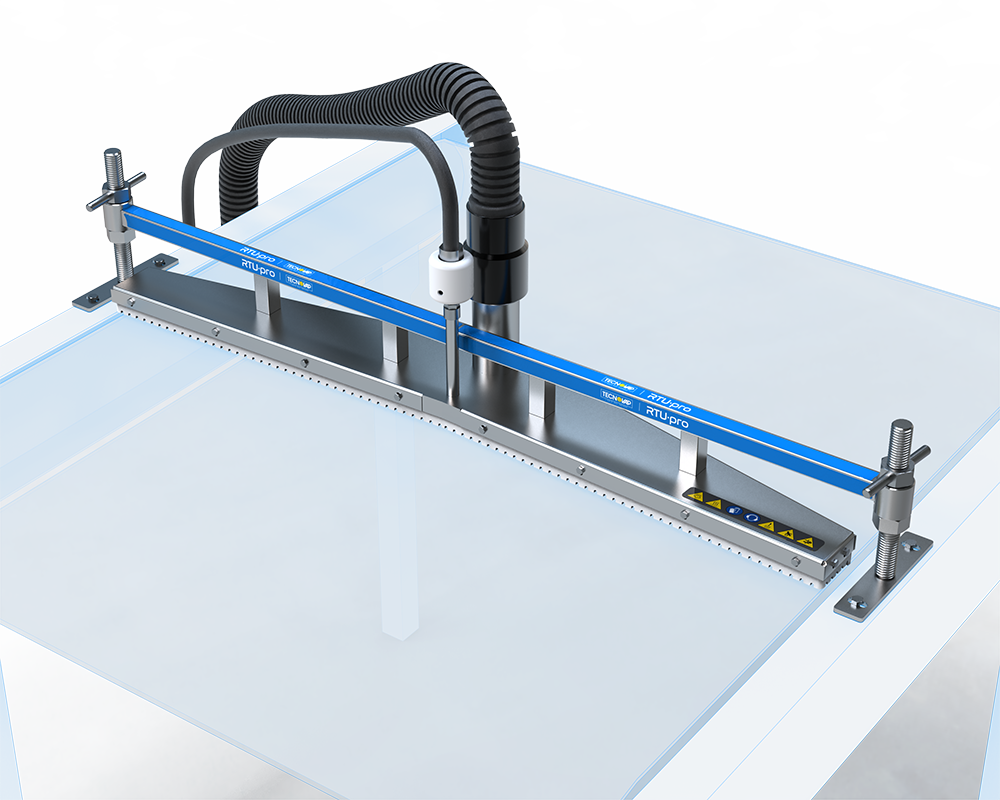

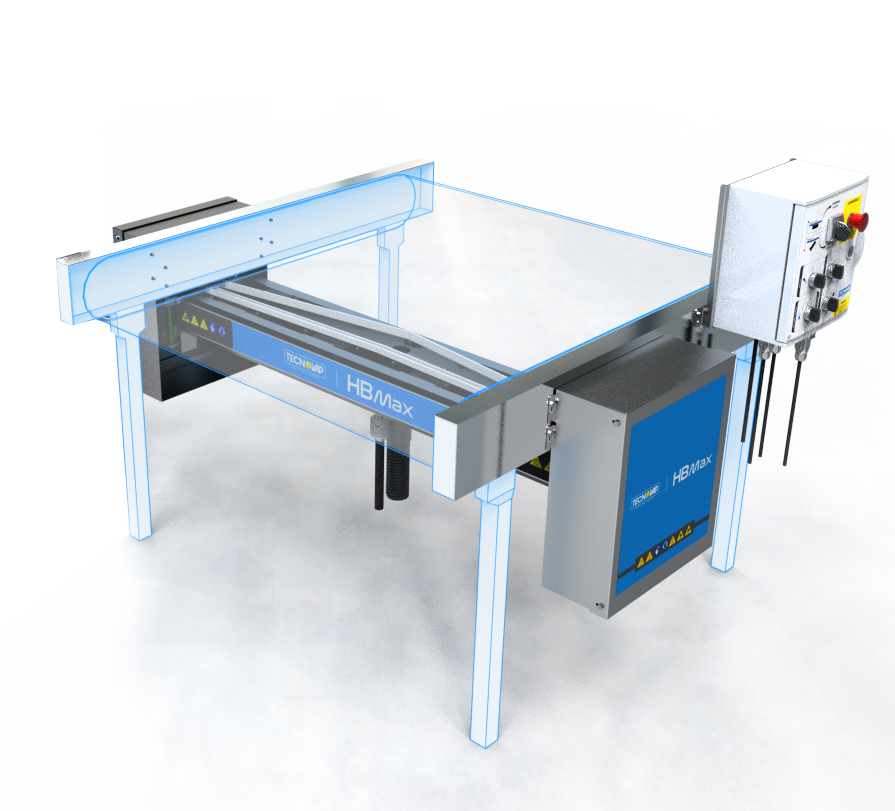

CLEANING HEAD POSITIONING

ON THE UPPER BELT

CLEANING HEAD POSITIONING

ON THE LOWER BELT

With this installation it is possible to clean the belt during the production cycle,

therefore optimizing costs and cleaning times.

CLEANING HEAD POSITIONING

ON THE UPPER BELT

CLEANING HEAD POSITIONING

ON THE LOWER BELT

With this installation it is possible to clean the belt during the production cycle,

therefore optimizing costs and cleaning times.

Documentation

Recommended steam generators:

Electric steam generators with power ratings from 8.4 kW to 39 kW, equipped with a stainless-steel body, boiler, and a vacuum cleaner with turbine.

In addition to belt cleaning, our steam generators can also be used for other applications within the company, such as cleaning of production machinery, tanks, cold rooms, walls, floors, and other surfaces.